Stuffing boxes are available in Economy, Premier and Pollution Control model types. Each of the 3 model types also comes in a variety of sizes and pressure capabilities. Learn more about each model type below:

Economy:

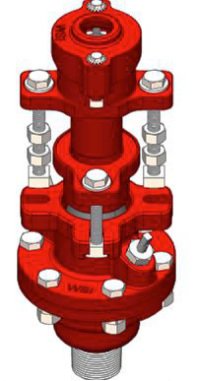

—— Economy Model’s - SPSB, TBSB & DPSB - 1500# ——

Single Packed Stuffing

Box (SPSB)

•Standard design

• Proven dependable performance

• Grease zerk

• Optional Oil Reservoir Gland (ORG) or Environmental Lube Upper Gland (ELUG™)

• Distinctive misaligning feature reducing need for exact pumping unit alignment

Tee Base Stuffing Box (TBSB)

• Combines stuffing box and pumping tee w/ 1” bleeder

• Eliminates one connection

• Side outlets:

-2” LP w/ 2” BTM connection

-3” LP w/ 2-1/2” or 3” BTM connection

• Grease zerk

• Optional Oil Reservoir Gland (ORG) or (ELUG™)

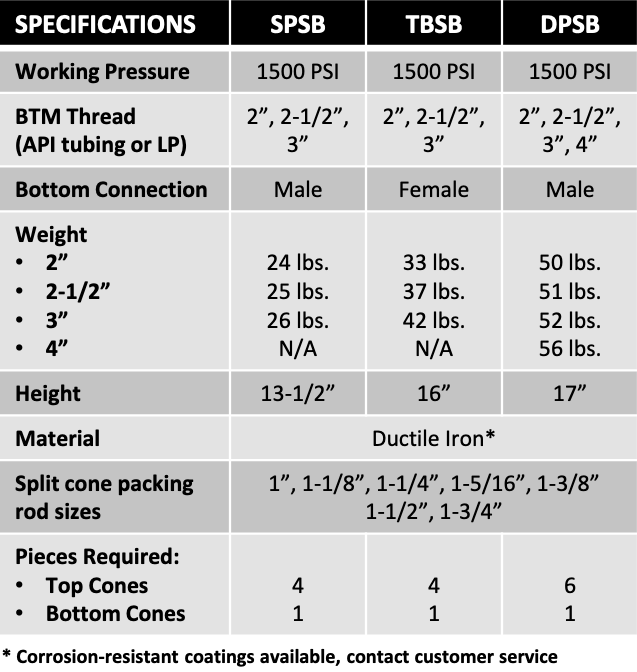

Double Packed Stuffing Box (DPSB)

• Most popular stuffing box in the

industry

• Grease zerk

• Distinctive misaligning feature reducing need for exact pumping unit alignment

• Optional Oil Reservoir Gland (ORG) or Environmental Lube Upper Gland (ELUG™)

• Proven dependable performance

These economy stuffing boxes in 1500# capabilities are available in the following size variations:

—— Economy Model’s - IVSB, IVTBSB & IVDPSB - 1500# ——

Inverted Stuffing Box

(IVSB)

• Lowest profile design

• Ideal for smaller pumping units

with minimum stroke length

• Inverted cone packing provides

additional surface contact and

wear characteristics

Inverted Tee Base Stuffing

Box (IVTBSB)

• Combines IVSB and pumping tee

with 1” bleeder

• Eliminates one connection

• Lower profile than Classic models

• Side outlets:

-2” LP w/ 2” BTM connection

-3” LP w/ 2-1/2” or 3” BTM connection

Inverted Double Packed

Stuffing Box (IVDPSB)

• Rugged built for performance under

tough oilfield conditions

• Lower profile than Classic model

• Proven dependable performance

• Inverted cone packing provides

additional surface contact and wear

characteristics

These economy stuffing boxes in 1500# capabilities are available in the following size variations:

Premier:

—— Premier Model’s - BSSP, BSTB™, BSDP - 1500# ——

Big Stuff Single Packed Stuffing Box (BSSP)

• Easy to adjust threaded cap – NO BOLTS (great in steam & high salt water cut area’s)

• Low profile design, ideal for short stroke pumping units

• Reduces costly packing maintenance time

• Even adjustment of packing every time!

• Convenient protection of packing when stacking out rods

• Available with or without ELUG™

Big Stuff Tee base Stuffing Box (BSTBTM)

• Easy to adjust threaded cap – NO BOLTS (great in steam & high salt water cut area’s)

• Eliminates one connection

• Low profile design, ideal for short stroke pumping units

• Standard brass inverter ring reduces polished rod scaring

• Even adjustment of packing every time!

• Available with or without ELUG™

Big Stuff Double Packed Stuffing Box (BSDP)

• Easy to adjust threaded cap – NO BOLTS (great in steam & high salt water cut area’s)

• Oil Field Grade rugged box, built for performance under tough conditions

• Lower profile compared to “Classic” model double packed stuffing box

• Even adjustment of packing every time!

• Two 1⁄4” NPT ports (180o apart) for grease zerk & pressure gauge

• Available with or without ELUG™

These premier stuffing boxes in 1500# capabilities are available in the following size variations:

—— Premier Model’s - PCDP(1.5K), BSPCDP(1.5K, 3K & 5K) ——

Pollution Control Double Packed (PCDP)

1500 PSI WP

• Meets NACE MR-01-75

• If polished rod breaks, flapper closes automatically

• Two independently adjustable packing chambers

• Base has 1⁄2” NPT test port

big stuff pollution control double packed Stuffing Box (BSPCDP)

3000 PSI WP

• Meets NACE MR-01-75

• If polished rod breaks, flapper closes automatically

• Easy to adjust threaded cap – NOBOLTS

• Super DomeTM style primary packing

• Two 1⁄4” NPT ports (180o apart) for grease zerk & pressure gauge

Big Stuff pollution control double packed Stuffing Box (BSPCDP)

1500 PSI WP

• Meets NACE MR-01-75

• If polished rod breaks, flapper closes automatically

• Easy to adjust threaded cap – NO BOLTS

• Super DomeTM style primary packing available for 1500 PSI model

• Two 1⁄4” NPT ports (180o apart) for grease zerk & pressure gauge

big stuff pollution control double packed Stuffing Box (BSPCDP)

5000 PSI WP

• Meets NACE MR-01-75

• If polished rod breaks, flapper closes automatically

• Easy to adjust threaded cap – NO BOLTS

• Two 1⁄4” NPT ports (180o apart) for grease zerk & pressure gauge

• Super DomeTM style primary packing

These premier models are available in the following sizes and pressure variations:

Upper glands

—— ELUG™, BSE-LUG™ and s-org™ ——

Environmental Lube Upper Gland (E-LUG™)

• Best design for leak detection glands

• Provides secondary seal for stuffing box

• Fits any “classic” style stuffing box

• Uses V style packing

• Adapts to any WSI “Environmental Protection Systems”

• Rod Sizes: 1” – 1-3/4”

• Body & cap: ductile iron

• Upper/lower packing rings: Brass/split optional

BS Environmental Lube Upper Gland (BSE-LUG™)

• Same features as above, but designed for “Premier” style stuffing box

• Adapts to any WSI “Environmental Protection Systems”

• Designed for “BS” stuffing boxes only

• Modified flange design connection, eliminates potential separation between E-LUG and Stuffing box

Standard Oil Reservoir Gland (S-ORG™)

• Option for wells that pump or flow off

• One quart reservoir capacity

• Utilizes Environmental Control Shut-down Switch unit (ECSS™)

• Top split cone wiper controls oil film on polished rod

• Rod sizes: 1” – 1-3/4”

• Material: ductile iron

• Fits any “Classic” style stuffing box

• Adapts to any WSI “Environmental Protection Systems”